Articles Blog

Follow Paganoni’s blog articles

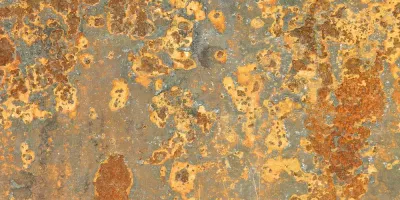

Corrosion resistance: a crucial foundation in industry

Corrosion is a natural process that silently consumes metals and other materials in a slow but inexorable process of deterioration. This phenomenon, which can be triggered by environmental factors, chemicals or other variables, is a constant enemy for …

Corrosion: why mechanical parts corrode?

Corrosion is a natural phenomenon that has plagued humankind since the dawn of industrialization. Its persistence in the modern world is often underestimated, but it is essential to understand its mechanisms and implications, especially when it comes t…

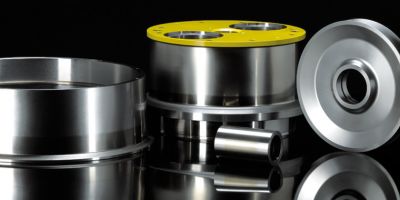

Wear and tear of mechanical components in industrial machines: problems and solutions

In the world of industrial machinery, wear and tear of mechanical components is an unavoidable and constant problem. Mechanical seals, in particular, play a crucial role in ensuring that machines operate efficiently. However, over time, these component…

Ceramic materials: everything you need to know about benefits and applications

The ceramic has been a material used for millennia due to its unique and unparalleled characteristics. Today, with the increasing demand for high-quality materials, ceramic has found new applications and uses.

But what exactly are the properti…

Ceramic extrusion: process, advantages, and innovations

The ceramic extrusion represents one of the fundamental techniques in the industrial ceramic sector. This processing method allows transforming ceramic materials into precise and detailed shapes, guaranteeing high-quality and precise products.In the co…

Tungsten carbide: characteristics, applications, and properties

Tungsten carbides are materials of paramount importance in the field of ceramic materials and powder metallurgy.

Known for their exceptional hardness and wear resistance, these carbides have established themselves as fundamental materials in v…

What are the benefits of zirconium oxide?

The zirconium oxide, although it may sound like a technical laboratory term, is actually at the heart of numerous innovations that touch various sectors of our daily life.

This extraordinary material, deeply linked to the world of ceramics, ex…

Precision mechanical details: when perfection is a requirement

In the modern industrial landscape, the demand for precision mechanical details is constantly growing. This demand is driven by the need for precision components that are reliable, durable, and produced with the tightest mechanical tolerances.

Thank…

Chromium carbides coatings: applications, properties, and related industries

The world of industrial materials is vast and fascinating, but few are as interesting and versatile as chromium carbides. These compounds, formed from chromium and carbon atoms, stand out for their extraordinary mechanical properties and are essential …

The revolution of 3D printing in the wire drawing industry

3D printing is fuelling an industrial revolution that is reshaping the manufacturing landscape at an unprecedented rate. In particular, the wire drawing industry is benefiting greatly from the innovations offered by industrial 3D printing.

Thi…

Corrosion protection in the aerospace sector

Corrosion protection is a key element in many industries, but it is particularly important in the aerospace sector.

Here, the durability and safety of structures and components are of critical importance, and corrosion can pose a significant t…

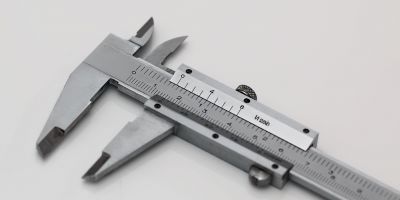

Dimensional control of shooting ranges: a guarantee of quality in production processes

In the industrial context, dimensional control assumes an absolutely prominent position. This quality control methodology, which involves the dimensional measurement of a component to verify its adequacy to dimensional tolerances, is essential not only…

Mining Industry: Innovations, Challenges, and Sustainable Solutions

The mining industry plays a fundamental role in our society, fueling the global economy and providing essential non-renewable natural resources for a myriad of industrial sectors.

As the extractive industry, including coal mines and gold mines…

Renewable Energy: Anti-Wear Coatings and Sustainable Solutions

Renewable energy, with the aid of innovation in the field of anti-wear coatings, is paving the way for a more sustainable future. These energy sources, including solar, wind, hydroelectric, geothermal, and biomass, are not only inexhaustible resources,…

Technical Ceramics: The Revolution in Advanced Ceramic Materials

Technical ceramics are revolutionizing the industrial sector with their unique properties and wide range of practical applications. These advanced ceramic materials, also known as engineering ceramics, are rewriting the rules of industrial applications…

The Ceramic Extrusion: Machines, Processes, and Technologies for the Production of Artifacts

The ceramic extrusion process is a crucial element in the ceramic industry, indispensable for the production of items such as tiles and various other articles. Thanks to extrusion, it is possible to shape clay, allowing the creation of designs of extra…

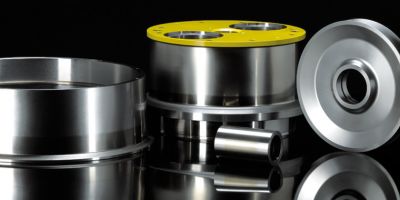

The Importance of Pulley Recovery in the Industrial Sector

In the world of industrial mechanics, the recovery of pulleys represents a crucial aspect for maintaining productivity in the workplace. and the efficiency of the machinery. On the one hand, it is a service that allows to extend the useful life of thes…

Chromium carbide: the solution for industrial coatings

In the metallurgical industry, chromium carbide emerges as a silent hero, playing a fundamental role in wear resistance and corrosion protection.

This compound of chromium and carbon is at the heart of numerous industrial processes, including chrome…

Zirconium Oxide: What it is and why it is important in Mechanical Coatings

Zirconium oxide, a ceramic material with extraordinary properties, is revolutionizing the world of mechanical coatings and many other industries. Discover the fascination of this unique compound, which guarantees exceptional durability and superior per…

Nickel Coatings: A Detailed Analysis of Material, Applications and Benefits

Nickel coatings are a process of applying a thin layer of nickel onto the surface of an object or component.

This type of coating can be used to improve corrosion resistance, increase hardness, improve electrical conductivity, or simply enhance the …

Technical Ceramics: Why Use Them in the Wire Drawing Industry

Technical ceramics are gaining ground in the industry thanks to their unique properties and numerous applications. In this article, we will focus on what technical ceramics are, what they are used for, and why they are an ideal option in the wire drawi…

Paganoni in Lecco: landmark for the wire drawing industry

Over the past 50 years, Paganoni in Lecco (Italy) has built a unique and impressive presence in the wire drawing industry. Our focus on high precision standards has enabled us to consistently provide products of unparalleled quality for a wide variety …

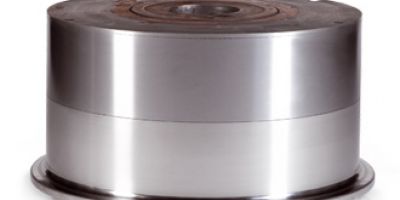

Dynamic balancing on mechanical parts: test certificate

Are you in the drawing industry and looking for a reliable process that will ensure that your production line moves quickly and efficiently, without causing stress on machinery or risk of damage to mechanical parts? If so, dynamic balancing may be the …

Ceramic coating for mechanical parts

Are you looking for a way to increase the life of your mechanical parts and make them more suitable for tasks that require increased wear resistance? A great option is ceramic coating, which has become an increasingly popular choice in the wire drawing…

Paganoni sales team: experience serving customers

Welcome to the Paganoni sales team! Our company has been a leader in the application of wear coatings for mechanical parts for over fifty years, and we are proud of our experience and commitment to customer service. We understand that the success of an…

Cabestan operation: what it is and when it is used

Are you a wire drawing professional and want to learn more about how cabestan works? If yes, you are in the right place! The cabestan is a winch used in wire drawing and shaping that has been around for centuries but continues to play an important role…

Anti-corrosion surface treatments for mechanical components

Did you know that corrosion is the leading environmental health and safety (EHS) problem among industrial manufacturers? That’s why it is so important to invest in proper anti-corrosion treatments for your mechanical components, machinery and equipment…

Parts for wire drawing machines: the best products

Wire drawing is a process used to create long, thin metal wires. The bundle drawing process uses a series of dies through which the metal is drawn, reducing its diameter and increasing its length.

To make this process possible, machines must have se…

Polishing mechanical parts: how to recover them

If you have ever worked with mechanical parts, you know how important it is to keep them clean and polished. But what to do when parts start to look dull and damaged? You cannot throw them away: too much money and effort has been invested.

Fortunate…

Sintered ceramic material: useful for mechanical parts

If you work in the drawing industry, you know that sintered ceramic material is a useful tool for creating mechanical parts.

But what exactly is sintered ceramic material? And how can it be used to create high-quality mechanical parts?

Read on to…

Wear-resistant ceramic coatings: why are they useful?

Welcome to the world of metalworking and drawing. If you work in this industry, you know that keeping your mechanical parts in perfect working order can be a challenge. But thanks to advances in ceramic coating technology, it no longer has to be a daun…

What is chromium oxide and its importance as a coating for mechanical parts

From medical equipment to vehicle parts, the use of chromium oxide coating is essential to protect many mechanical components from wear and tear. But what exactly is chromium oxide? How does it improve the performance and durability of components?

I…

What is chemical nickel plating?

Are you part of a wire drawing industry? Or do you simply need to learn more about the process and know what chemical nickel plating is? Either way, this post is for you! Chemical nickel plating is an important part of industries that require reliable …

Pulley and sheave: the importance of a quality coating

Many companies find themselves in need of pulley sheaves, especially when transporting heavy goods. These components are subject to wear over time, due to the friction generated by handling goods.

For this reason, it is essential to use pulleys with…

Anti-corrosion coatings for mechanical parts: the advantages

Anti-corrosion coatings are essential to protect mechanical parts from corrosive attack. Corrosion can seriously damage metal parts, thus compromising the functionality of the entire component. Anti-corrosion coatings prevent this deterioration process…

Coatings for precision mechanical components: which ones are best

Coatings for precision mechanical components are essential to ensure maximum wear resistance and long life of mechanical components. In this article we will explain which are the best coatings for your components, and how to choose them according to yo…

Ceramic wire guide rollers: the advantages of ceramic coating

Ceramic is an innovative solution for coating yarn guides. These rollers have several advantages over those made of other materials. First of all, ceramic is a resistant material that guarantees a long life. In addition, the ceramic has a high resistan…

Mechanical details: the advantages of the wear-resistant coating

Mechanical parts are essential components in many industrial sectors. The production of mechanical parts requires great attention to detail, especially when it comes to wear-resistant coatings. These coatings are very important to protect the mechanica…

Tungsten carbide coating: why is it recommended?

Tungsten carbide is a very hard and high temperature resistant material, which is used to make particularly wear resistant coatings. This type of coating is particularly suitable for drawing reinforced concrete wire with a modified structure, as it gua…

Worn capstan: here’s how to recover it

What is the capstan? This is a question you may have heard before but are unsure of the answer. Capstan is a type of winch used for pulling heavy objects. It has two main parts: the capstan itself and the cable.

The capstan is attached to the object…

How to recover worn idler pulleys

Idler pulleys are used in a transmission or conveyor system. They absorb the slack or movement on the return side of the belt and keep the belt taut. In most cases, it is very important to use idler pulleys in excellent condition to avoid premature wea…

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy

Powered by Indo Consulting.