Ceramic materials: everything you need to know about benefits and applications

Blog and news on the world of wear-resistant coatings

Ceramic materials: everything you need to know about benefits and applications

The ceramic has been a material used for millennia due to its unique and unparalleled characteristics. Today, with the increasing demand for high-quality materials, ceramic has found new applications and uses.

But what exactly are the properties of ceramic materials that make them so special? And in which areas can they be best utilized? In this article, we will explore the advantages of ceramic materials, their different types, and the latest trends in this field.

Properties and characteristics of ceramic materials

Ceramic materials are known for their strength, durability, and versatility. One of the main features of ceramic materials is their ability to withstand high temperatures. This makes them ideal for use in ceramic kilns and other high-temperature applications.

Thanks to ceramic insulators, these materials can maintain their properties even under extreme conditions, making them essential in many industrial sectors.

READ ALSO: Technical ceramic: the breakthrough in advanced ceramic materials

Durability and strength

One of the main advantages of ceramic materials is their incredible durability. They can resist corrosion, wear, and can maintain their properties over long periods.

Versatility

Ceramic tools, such as knives or scissors, are appreciated for their ability to retain their sharpness longer than other materials. Additionally, ceramic glazes and paints offer endless customization possibilities, from coloring to finishing.

Types of ceramic materials and their applications

There are various types of ceramic materials which vary based on composition and properties. These include traditional ceramics, porcelain, terracotta, and many more.

The applications of ceramic materials are vast. While ceramic sculptures are valued in the artistic field, in the industrial sector we find mechanical components, electronic parts, and much more.

Production process and latest trends in ceramic materials

The production process of ceramic materials begins with the selection of raw materials, followed by shaping, firing in kilns, and finally, finishing. During this process, glazes or paints can be added to customize the final product.

Regarding the latest trends in ceramic materials, we see a growing interest in sustainable and low environmental impact materials, as well as the search for new alloys and compositions to further improve performance.

READ ALSO: Mining Industry: innovations, challenges, and sustainable solutions

Innovation in the ceramic field with Paganoni

Paganoni, a renowned division of Mario Nava S.p.A., has embarked on a path of specialization in the field of ceramic materials since the 1970s.

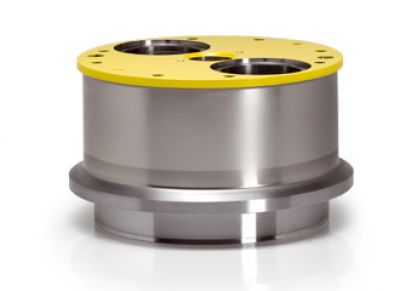

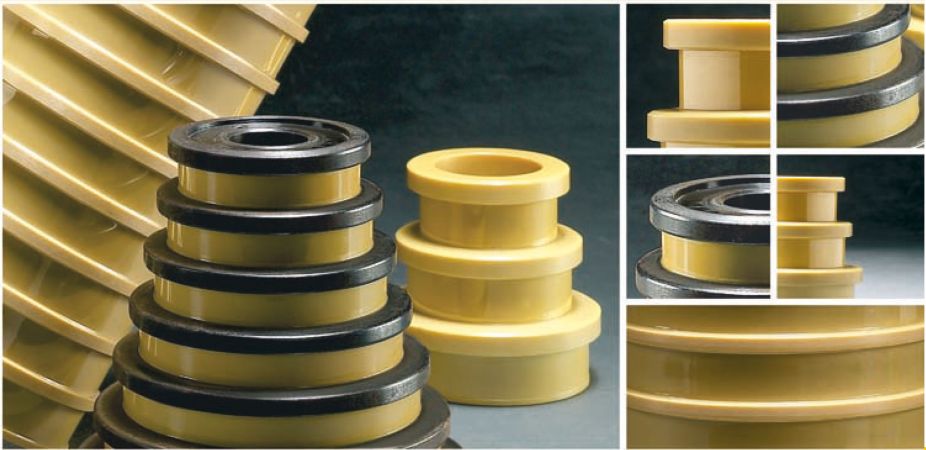

After years of in-depth research and field tests, the company has refined its skills, specializing in creating wear-resistant coatings and technical ceramics, especially for the wire drawing industry. A significant capability of the company is to restore the geometries of parts damaged by friction and wire passage, ensuring greater longevity and efficiency of industrial tools.

Paganoni also stands out for its use of cutting-edge materials: it uses a super-sintered ceramic material composed of zirconium oxide and rare minerals, ensuring high-quality and resilient coatings. The deep understanding of ceramic materials and decades of experience in the sector make Paganoni a point of reference in the industry.

Perché scegliere Paganoni?

The benefits of ceramic materials are many and varied. From their resistance to wear and high temperatures to their vast range of applications in various sectors, ceramics continue to be a fundamental part of modern industry.

Companies like Paganoni are at the forefront of innovation in this field, constantly seeking to improve and refine their products and processes to meet the needs of an ever-evolving market.

For those interested in diving deeper into this world, Paganoni offers consulting and specialized products to ensure the highest quality and performance in the ceramic sector.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy