Pulley and sheave: the importance of a quality coating

Blog and news on the world of wear-resistant coatings

Pulley and sheave: the importance of a quality coating

Many companies find themselves in need of pulley sheaves, especially when transporting heavy goods. These components are subject to wear over time, due to the friction generated by handling goods.

For this reason, it is essential to use pulleys with an anti-corrosion and anti-seize coating to prolong their life.

What is a pulley and what is it used for?

A pulley is a motion transmission organ characterised by one or more grooved wheels and a rope, chain or cable forming a loop around them. They are used to change the direction of force, lift heavy objects and reduce the amount of effort required to perform a task.

For example, if you have ever taken a lift, you have taken advantage of these important mechanical parts. With several pulleys connected in a lift system, you can easily move between floors with minimal force. Pulley systems have existed for centuries to perform mundane tasks such as lifting buckets from wells and transporting goods from the holds of ships. Even today they are used in modern technology, such as odometers and speedometers in cars.

The different types of pulleys

Have you ever been curious about pulleys? Pulleys are an excellent tool for changing the direction and intensity of force, which makes them very useful in everyday life. A pulley essentially consists of a wheel and a rope; when one end of the rope is pulled, the wheel moves, changing the direction or intensity of the force.

There are different types of pulleys, each suited to specific needs.

- Fixed pulleys are generally used to change the direction of a pulling force by maintaining the effort and moving one end in a different direction.

- Moving pulleys allow manual lifting from fixed positions and can offer some reduction in effort compared to fixed pulleys.

- Composite pulleys allow even greater effort reduction, as multiple strands of the rope provide additional movement for each pull.

- Finally, block systems offer a greater mechanical advantage over any other type of simple inclined plane equipment due to their dual mechanism system, which allows heavier loads to be moved with relatively little effort.

Read also Solutions for the wire-drawing industry

Why is a quality coating important for a pulley system?

It is no secret that pulleys are subject to intensive use and wear over time, so it is important to ensure that they are properly cared for. One way to do this is to use a quality coating. A quality coating protects the pulleys from weathering, corrosion and abrasive particles.

Read also The importance of wear-resistant coatings for mechanical parts

In addition, this type of protective layer can help improve the pulley’s ability to transmit power efficiently and reduce noise levels between rotating parts. As you can see, quality coatings on pulleys are essential to avoid costly damage in the future and to make pulleys work as they should.

What coating to choose for a pulley?

Although most pulleys are made of metal, it is the coating that is applied to this metal – and not the metal itself – that determines its suitability for different types of applications and durability.

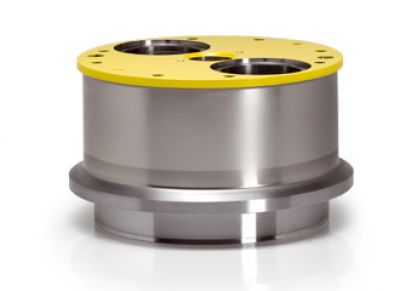

Paganoni’s anti-corrosion and anti-seize coatings allow for greater durability and strength through careful and meticulous design.

Want to know more? Request information today and one of our experts will contact you shortly.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy