Mechanical details: the advantages of the wear-resistant coating

Blog and news on the world of wear-resistant coatings

Mechanical details: the advantages of the wear-resistant coating

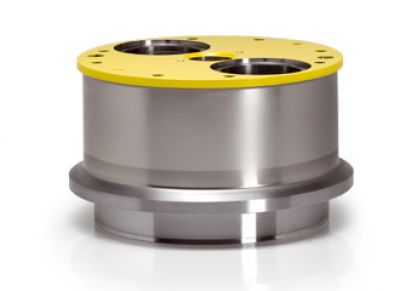

Mechanical parts are essential components in many industrial sectors. The production of mechanical parts requires great attention to detail, especially when it comes to wear-resistant coatings. These coatings are very important to protect the mechanical parts from wear and damage.

In this article, we will talk about the production of mechanical parts and the importance of coatings.

What is a wear coating and what are its benefits for mechanical parts?

The term “wear coating” may not sound familiar, but it is actually a crucial element in extending the life of many mechanical parts. These coatings are applied to metal surfaces and act as a barrier against friction, essentially reducing wear on parts. This can be particularly useful in industries such as automotive or manufacturing, where machinery regularly experiences high levels of friction and stress.

Read also: The importance of wear-resistant coatings for mechanical parts

Without a wear-resistant coating, these mechanical components would have to be replaced more frequently, resulting in increased downtime and costly repairs. By opting for coated components, companies can save in the long run and keep their businesses running smoothly. And above all, these coatings are customizable and allow you to obtain a specific wear resistance based on the needs of each sector or application. So, the next time you hear about a wear coating, remember how important it is to keep your machinery running at its best.

How does a wear resistant coating work and how long will it last on a piece?

Have you ever noticed that some mechanical parts seem to resist wear longer than others? They are likely to have a wear resistant coating. These coatings typically consist of a combination of hard materials, such as ceramic or diamond, and lubricants that reduce friction. This creates a protective barrier against abrasion, corrosion and extreme temperatures.

Discover Paganoni, manufacturer of wear-resistant coatings for mechanical parts

The longevity of these coatings depends on the specific materials used and the conditions in which they are applied. However, with proper application and maintenance, they can last for years on parts like gears and valves where constant friction is an issue. So, next time you want to extend the life of your mechanical components, consider investing in a wear resistant coating.

How do you know if a part needs to be coated with a wear resistant material and where can you get more information on this process?

Thank you for joining us as we explored the world of wear coatings! We hope you now understand what these coatings are, how they work and some of their benefits.

If you are interested in learning more about how to apply this technology to your mechanical parts, do not hesitate to discover Wolside® coating, the best on the market. Our Paganoni team will be happy to discuss the possibilities with you and help you get started using wear-resistant coatings to improve your products.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy