Anti-corrosion coatings for mechanical parts: the advantages

Blog and news on the world of wear-resistant coatings

Anti-corrosion coatings for mechanical parts: the advantages

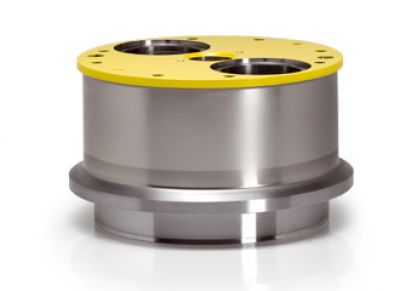

Anti-corrosion coatings are essential to protect mechanical parts from corrosive attack. Corrosion can seriously damage metal parts, thus compromising the functionality of the entire component. Anti-corrosion coatings prevent this deterioration process, thus ensuring the durability and strength of the item.

In this article, we will look at the main advantages of this type of coating.

What are anti-corrosion coatings and what do they do?

Anti-corrosion coatings are coatings or layers of chemicals that are applied to the surface of components and mechanical parts to protect them from corrosion over time. This protective layer helps reduce deterioration due to exposure to air, moisture and other elements in the environment.

These anti-corrosion coatings help create longevity and resilience for machinery that might otherwise deteriorate rapidly if left unprotected. It is essential to help extend the life of these components and parts, ultimately saving on maintenance costs.

The benefits of using anti-corrosion coatings on mechanical parts

The use of anti-corrosion coatings on mechanical parts can be extremely advantageous. This type of coating offers protection against exposure to harsh environmental conditions, as well as against erosion and rusting caused by moisture or chemicals. It can also help extend the life of mechanical parts and increase their efficiency by blocking dust, dirt and particles that could damage them.

Read aldo Tungsten carbide coating: why is it recommended?

Using an anti-corrosion coating saves money in the long run, as it preserves the performance of mechanical parts for much longer. Moreover, these coatings are generally easy to apply and require minimal maintenance. This gives you one less thing to worry about to keep your project running smoothly. All these advantages make anti-corrosion coatings an excellent option for protecting mechanical components from wear and tear.

How to choose the right anti-corrosion coating for your needs

The choice of an anti-corrosion coating for a given industry is extremely important. Quality corrosion protection can drastically reduce maintenance and repair costs, while reducing downtime due to part replacement and breakage. Anti-corrosion coatings provide a layer of protection on multiple fronts, repelling moisture, dirt, chemicals, UV exposure, salt water and other corrosive materials.

Discover also Mechanical details: the advantages of the wear-resistant coating

Ultimately, how do you choose an anti-corrosion coating? When you choose an effective protective coating for your industry, you will be able to minimise the wear and tear on parts and equipment that can occur during daily operations. An anti-corrosion coating should be the top priority of any preventive maintenance plan to ensure optimal performance and durability.

Quality anticorrosion coatings: Paganoni coatings

Anti-corrosion coatings are an important investment for any company that uses mechanical parts. They protect equipment from corrosion, which can lead to reduced performance and costly repairs.

Paganoni coatings are the best on the market and offer a range of benefits for companies of all sizes. Request more information today to find out how Paganoni can help you extend the life of your mechanical parts.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy