Zirconium Oxide: What it is and why it is important in Mechanical Coatings

Blog and news on the world of wear-resistant coatings

Zirconium Oxide: What it is and why it is important in Mechanical Coatings

Zirconium oxide, a ceramic material with extraordinary properties, is revolutionizing the world of mechanical coatings and many other industries. Discover the fascination of this unique compound, which guarantees exceptional durability and superior performance in a multitude of applications.

Not everyone is familiar with this material and its special features, so today you will discover what it is and how it is used.

What is zirconium oxide?

Zirconium oxide, also known as zirconia, is a chemical compound with the formula ZrO2. It is a polycrystalline ceramic material that occurs as a colorless, odourless and non-flammable solid. Zirconia is characterised by high mechanical, chemical and thermal properties, including remarkable corrosion resistance, high hardness and good thermal stability.

DISCOVER THE USE OF ZIRCONIA IN OUR COMPANY

What are the uses of zirconium oxide?

Zirconium oxide has applications in a wide range of sectors due to its excellent properties. Below are some of its main uses:

Dentistry

In dentistry, zirconia is used in the manufacture of dental crowns and bridges, as well as implants, due to its biocompatibility, strength and ability to blend in with the appearance of natural teeth.

Electronics

Zirconium oxide is used in the manufacture of electronic components and solid-state devices, such as oxygen sensors and ceramic capacitors, due to its thermal stability and dielectric properties.

Aerospace and automotive industry

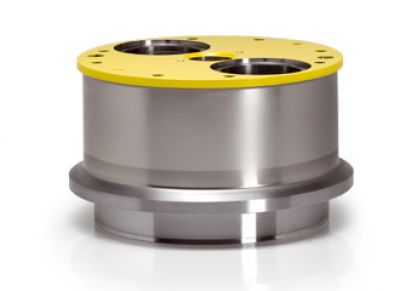

In the aerospace and automotive industries, zirconia is used to produce wear- and corrosion-resistant components such as seals, bearings and engine parts.

Why is zirconia important as a coating for mechanical parts?

Zirconium oxide is an ideal material for coating mechanical parts due to its many properties, including:

Wear resistance

Zirconia is extremely wear-resistant, making it ideal for protecting mechanical parts subjected to friction and rubbing.

Read also What is chromium oxide and its importance as a coating for mechanical parts

Corrosion resistance

Zirconia is known for its resistance to corrosion, even in chemically aggressive environments, ensuring the durability and reliability of coated mechanical parts.

Thermal stability

Zirconia possesses high thermal stability, allowing it to retain its properties even at high temperatures. This makes it suitable for coating components operating in extreme heat conditions, such as in the aerospace and automotive industries.

Biocompatibility

The biocompatibility of zirconia also makes it suitable for medical and dental applications, where material safety and tolerability are paramount.

Read also Anti-corrosion coatings for mechanical parts: the advantages

Lightness and rigidity

Despite its lightness, zirconia offers exceptional stiffness, making it ideal for applications where low weight must be maintained without compromising mechanical performance.

In conclusion, zirconia is a material with unique characteristics and multiple uses, ranging from dentistry to electronics and the aerospace and automotive industries. Its importance as a coating for mechanical parts is mainly due to its resistance to wear, corrosion and high temperatures, as well as its biocompatibility and its lightweight and stiff properties.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy