What is chemical nickel plating?

Blog and news on the world of wear-resistant coatings

What is chemical nickel plating?

Are you part of a wire drawing industry? Or do you simply need to learn more about the process and know what chemical nickel plating is? Either way, this post is for you! Chemical nickel plating is an important part of industries that require reliable and durable connections such as wire harnesses, electronics and other hardware components.

In this article we will explain exactly what chemical nickel plating is, why it is so important and how it can benefit your company or application. Read on to learn more about the process of creating a chemically bonded metal surface!

What is nickel plating and what are the advantages of its use

Nickel plating is a chemical process that applies a thin layer of nickel to the surface of another material, such as steel or plastic. It is used in industry for a range of sectors, from automotive to aerospace and chemical processing. The main advantage of nickel plating is that it provides protection against corrosion and can also be used to increase the hardness and wear resistance of a material.

Nickel plating also results in longer product life, better appearance, higher conductivity and reduced maintenance costs. For these reasons, chemical nickel plating is commonly used in many industrial applications.

What is nickel plating and what are the advantages of its use

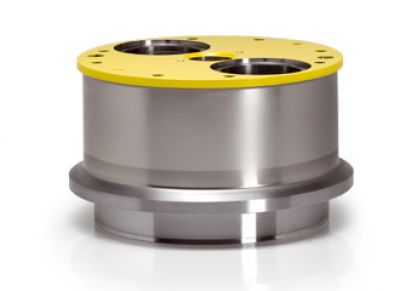

Discover Paganoni’s line of Nickel-based Niksint® coatings

The different types of nickel plating and how each is used

Nickel plating is an incredibly useful chemical process for various industrial purposes. It can refer to two basic chemical processes: electroless nickel plating and chemical nickel plating. The process of electroless nickel plating involves the use of electric current to reduce a salt of the desired metal from its liquid form by depositing the metal on the surface of a base. Chemical nickel plating, on the other hand, involves the use of chemical baths in combination with heat and electricity to plate the surface with vapourised metals.

Each type of nickel plating has different purposes, and is therefore ideal for many engineering operations, such as protecting objects from corrosion and wear, improving appearance and creating electrically conductive surfaces that allow for quick and easy soldering or brazing.

Read also The importance of wear-resistant coatings for mechanical parts

The Importance of Nickel Plating for Protecting Mechanical Components from Corrosion and Wear

Have you ever wondered how metal parts stay shiny and rust-free for years? The secret lies in chemical nickel plating! Nickel plating, also known as electroless nickel plating or nickel electroplating, is a process in which a very thin layer of pure nickel is applied to the surface of mechanical components.

This very thin layer acts as a barrier between the component and its environment and protects it from corrosion and wear. Nickel plating helps preserve the appearance of metal products, making them last longer with minimal maintenance or repair over time. For these reasons, it is an ideal option for preventing damage and extending the life of valuable tools, car parts and other important mechanical components.

Want to know more about nickel-coated components?

Chemical nickel plating, as we have seen, is a process that uses an electric current to coat metal with a thin layer of nickel. This process offers many advantages, including increased durability, resistance to corrosion and wear, and improved appearance.

If you are looking for superior corrosion and wear protection for your mechanical components, consider Paganoni’s nickel-coated product line.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy