Coatings for precision mechanical components: which ones are best

Blog and news on the world of wear-resistant coatings

Coatings for precision mechanical components: which ones are best

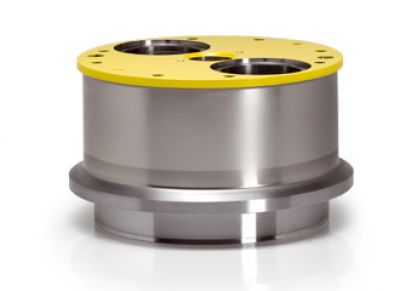

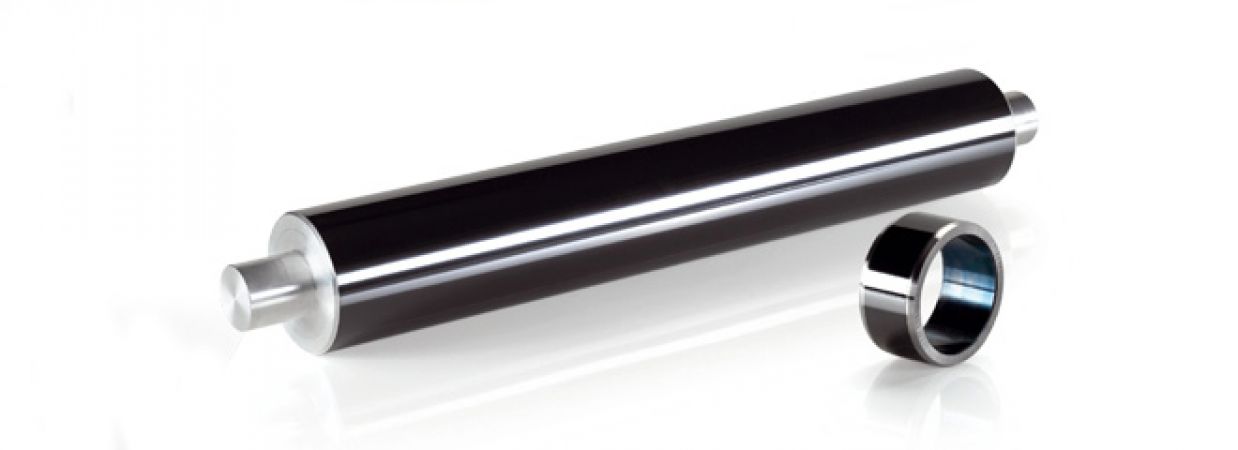

Coatings for precision mechanical components are essential to ensure maximum wear resistance and long life of mechanical components. In this article we will explain which are the best coatings for your components, and how to choose them according to your specific needs. Don’t miss this opportunity: coating your mechanical components with a durable material is crucial for the success of your system.

Let’s find out together.

What coatings are available for precision mechanical components and what are their advantages?

Coatings for precision mechanical components are a great way to ensure the longevity of your parts and maximise their performance. Coatings are a popular choice to extend the life of mechanical components, reduce wear, protect against corrosion and high temperatures, and improve aesthetics. Coatings also provide better lubrication, greater strength, lower coefficients of friction and cleaner surfaces.

Coatings range from electrolytic nickel plating to zinc alloys, from ceramic composites to silicon oxide, from PTFE (commonly known as Teflon) to diamond carbon coatings. Each type of coating offers different advantages, which must be evaluated to determine which is best suited to your application. Coatings can make all the difference in the efficient operation of precision mechanical components!

Factors to consider when choosing a coating for precision mechanical components

The machining industry is based on precision, and one of the most important aspects is the use of the right coating for components. Coatings play an important role in protecting parts from wear, corrosion and other external elements, and choosing the right coating for your precision mechanical components is crucial.

Discover more How to recover worn idler pulleys

When choosing a coating, several factors must be considered: the environmental conditions in which the component will operate; the machining process; the operating temperature; material compatibility; durability versus cost; and desired aesthetics. All these considerations can help you decide on the most suitable coating to achieve maximum performance in your particular machining application.

How to choose the best coating for your needs

Choosing the right coating for your precision mechanical components can be difficult. Coatings are designed for specific applications and conditions, so it is important to get professional advice to make the best decision for your project.

Read also Worn capstan: here’s how to recover it

Advice from a specialist can provide valuable guidance on the most suitable coatings for your needs, ensuring you choose the material that offers the highest level of protection, longevity and performance. With their guidance, you can easily choose the ideal coating and reap all the benefits.

Free advice on the best siding

When it comes to choosing a coating for your precision mechanical components, there are many factors to consider and different types of coatings available.

Paganoni’s experts have years of experience in helping customers find the best coating for their needs and offer a free consultation to get started. If you are unsure of the most suitable cladding for your project, contact us. We will be more than happy to provide you with a free consultation.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy