Ceramic wire guide rollers: the advantages of ceramic coating

Blog and news on the world of wear-resistant coatings

Ceramic wire guide rollers: the advantages of ceramic coating

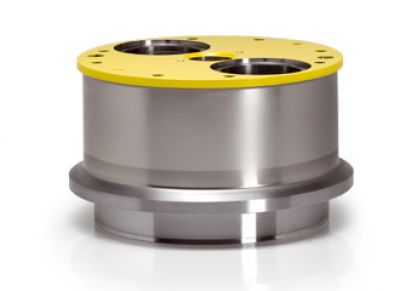

Ceramic is an innovative solution for coating yarn guides. These rollers have several advantages over those made of other materials. First of all, ceramic is a resistant material that guarantees a long life. In addition, the ceramic has a high resistance to wear and chemicals. These characteristics make the ceramic wire guide rollers ideal for applications in particularly aggressive environments.

Let’s discover together the features and advantages of using ceramic wire guide rollers.

What are ceramic wire rollers and what are their advantages over traditional steel wire rollers?

Have you ever heard of ceramic wire guide rollers? These specialized rolls are used in industries such as paper making, wire making and wire drawing. But what distinguishes them from traditional steel wire guide rollers?

For starters, ceramic rollers have a lower coefficient of friction and higher wear resistance, which results in less maintenance downtime and higher productivity. In addition, they offer superior thermal conductivity, which allows you to better control the temperature during the manufacturing process.

Discover the best ceramic coating for your mechanical parts

Last but not least, ceramic rollers are non-magnetic and non-sparking, making them a safer option for some industries. The next time you see a ceramic wire guide roller in action, you will know how valuable it can be.

How the ceramic coating is applied to the wire guide rollers

When it comes to wire guide rollers, ceramic coating is a great choice for reducing friction and wear. First, we need to make sure the roller surface is clean and free of debris. Next, we apply a thin layer of ceramic paste with an applicator or brush. Only once the coating has hardened according to the instructions of the expert technicians can the roller be used in production.

Find out more about specialized coating manufacturers for parts

Finally, let’s consider applying a second layer for added durability and longevity. Remember to periodically and regularly inspect and clean the rollers so they will continue to perform at their best.

Ceramic wire guide rollers manufacturers

Ceramic wire guide rollers are becoming increasingly popular in the industry, and for good reason. Their ceramic coating offers a number of advantages over traditional steel wire guide rolls, including longer life, better accuracy and wear resistance.

If you are interested in learning more about ceramic wire guide rollers or want to find a supplier who can provide you with the best products on the market, contact us today. Paganoni specializes in the production of ceramic wire guides. It produces the Kersint® Coating, a super-sintered ceramic material based on zirconium oxide and rare minerals.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy