Tungsten carbide: characteristics, applications, and properties

Blog and news on the world of wear-resistant coatings

Tungsten carbide: characteristics, applications, and properties

Tungsten carbides are materials of paramount importance in the field of ceramic materials and powder metallurgy.

Known for their exceptional hardness and wear resistance, these carbides have established themselves as fundamental materials in various industrial applications.

In this article, we will delve into the properties of tungsten carbides, their main applications, and why you might consider turning to a specialized company like Paganoni.

Properties of tungsten carbides

The tungsten, the main element of this alloy, forms compounds known as tungsten carbides. Their unique molecular structure gives these materials exceptional mechanical properties.

READ ALSO: The Importance of pulley recovery in the industrial sector

Mechanical properties of tungsten carbides

In addition to the aforementioned hardness, these carbides boast high wear resistance. Their coefficient of thermal expansion is notably low, while their thermal conductivity coefficient is relatively high.

Characteristics of tungsten carbides

The high melting temperature and wear resistance make tungsten carbides particularly suitable for high-temperature applications and under intense wear conditions.

Tungsten carbides and other alloys

In addition to being used alone, tungsten carbides are often combined with other alloys to further enhance their properties. For instance, when mixed with cobalt, they form “hard metal“, which combines the hardness of the carbide with the ductility of cobalt.

READ ALSO: Anti-corrosion coatings for mechanical parts: the advantages

Use of tungsten carbides

These materials are used in a wide range of sectors, from the aerospace industry to jewelry. They are ideal for cutting tools, drill bits, and wear-resistant components in industrial machines.

Production of tungsten carbides

The production process begins with sintering. Sintered tungsten carbide is obtained through the powder metallurgy technique. This technique involves using heat and pressure to transform the tungsten and carbon powder into a compact solid.

Read also Tungsten carbide coating: why is it recommended?

Heat treatments for tungsten carbides

Heat treatments are essential to further improve the properties of the carbides. Through these processes, it is possible to optimize hardness, wear resistance, and other key properties of the carbides.

In conclusion, thanks to their exceptional properties, tungsten carbides represent a fundamental choice for many industrial applications. The importance of their correct processing and application is essential to ensure the best performance.

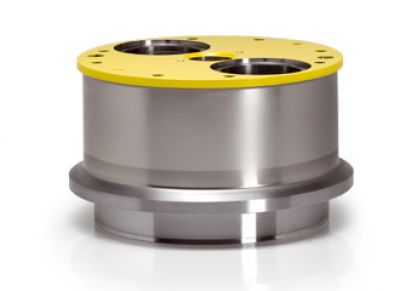

Discover on Paganoni the Coldside@ coating in tungsten carbides

And this is where Paganoni comes into play. Specialized in tungsten carbide coatings, Paganoni not only provides high-quality solutions but also offers a wide range of customizations based on specific customer needs. Whether you need a particular coating for an industrial machine or wish to improve the wear resistance of a component, Paganoni has the expertise and experience required.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy