Corrosion: why mechanical parts corrode?

Blog and news on the world of wear-resistant coatings

Corrosion: why mechanical parts corrode?

Corrosion is a natural phenomenon that has plagued humankind since the dawn of industrialization. Its persistence in the modern world is often underestimated, but it is essential to understand its mechanisms and implications, especially when it comes to the corrosion of mechanical components used in industrial machinery.

In this article we will explore the causes of corrosion, the importance of maintaining a high level of mechanical components, the use of protective coatings, and the crucial role played by companies like Paganoni in the industrial sector.

Corrosion: what does it consist of?

Corrosion is the result of a chemical reaction between metal and its environment. Mechanical components, often made of metal alloys, are particularly susceptible to this phenomenon.

Common corrosive agents include moisture, acids, bases, oxygen and other chemical compounds. Corrosion can occur in various forms, such as rust, uniform corrosion, or galvanic corrosion, depending on the conditions and materials involved.

The importance of intact mechanical components

Industrial machines depend on the precision and functionality of their mechanical components. Corrosion of these parts can lead to failures, malfunctions and even accidents in the workplace. Maintaining a high level of mechanical components is essential to ensure the safety, efficiency and durability of industrial machines.

Read also Wear and tear of mechanical components in industrial machines: problems and solutions

In addition, the constant replacement of corroded mechanical parts contributes to increased maintenance costs and lost production. Therefore, corrosion prevention becomes a crucial goal for industry.

The use of protective and quality coatings

One of the main strategies for preventing corrosion of mechanical parts is the application of protective coatings. These coatings create a barrier between the metal and corrosive agents, preventing direct contact. Choosing the right coating is critical, as it depends on the type of metal, environmental conditions and the intended use of the machine.

Some of the most common coatings include galvanizing, plastic coating, paint and chrome plating, ceramic, and more.

Paganoni: a leader in anti-corrosion coating

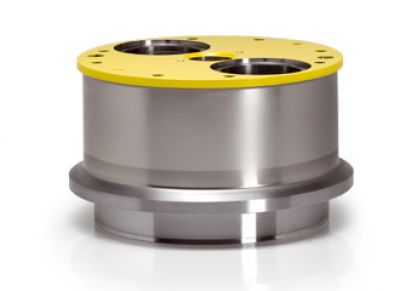

Paganoni is a leading name in the anti-corrosion coating industry for mechanical parts for the wire drawing industry. The company has earned a high reputation due to its expertise, quality of services and constant innovation in the field of protective coating.

Discover also Worn capstan: here’s how to recover it

Their range of solutions is custom-designed to meet customers’ specific needs, ensuring maximum protection against corrosion. In addition, Paganoni stands out for its focus on sustainability, using technologies and processes that reduce environmental impact, contributing to a greener future for the industry.

Need a quote or consultation?

Corrosion is a serious problem for mechanical parts used in industrial machinery. To ensure the safety, efficiency and longevity of industrial equipment, it is essential to take preventive measures, such as the use of quality coatings.

Do you know the our coating KERSINT®? Super-sintered technical ceramic material made of zirconium oxide and special minerals.

Companies like Paganoni play a key role in offering advanced solutions to combat corrosion and ensure the longevity of mechanical components in the wire drawing industry. Investing in the protection of mechanical components is an investment in the durability and safety of the entire production process.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy