Tungsten carbide coating: why is it recommended?

Blog and news on the world of wear-resistant coatings

Tungsten carbide coating: why is it recommended?

Tungsten carbide is a very hard and high temperature resistant material, which is used to make particularly wear resistant coatings. This type of coating is particularly suitable for drawing reinforced concrete wire with a modified structure, as it guarantees greater resistance to abrasion than traditional steel coatings.

Let’s find out together the advantages of the tungsten carbide coating and why it is recommended.

What is tungsten carbide coating and what are its advantages?

Have you ever heard of tungsten carbide coating? If not, you are not alone: it is a relatively new technology in the industrial world. What are tungsten carbide coatings? This is a process in which tungsten carbide particles are fused with the metal to create a strong coating. This coating can have many benefits for all types of industries, from construction to automotive.

One of the main advantages is the longer service life. The fusion of tungsten carbide causes the coated metal to resist wear much better than unprotected metal, providing better performance and longevity. Another advantage is the reduction of friction: the tungsten carbide particles offer greater smoothness and better overall operation.

Read also: The importance of wear-resistant coatings for mechanical parts

Finally, tungsten carbide coated tools can offer better resistance to chemicals and high temperatures. So, next time you need durable equipment for your job, consider the tungsten carbide coatings option.

Which Industries Commonly Use Tungsten Carbide Coating Services?

Did you know that tungsten carbide coatings is used in many industries other than simple wire drawing? In fact, it is commonly used in metalworking industries such as machining, drilling and stamping. This tough coating helps increase the life and efficiency of the tools used in these processes.

It can also protect against wear and corrosion in industries such as automotive manufacturing and oil production. The textile industry also uses tungsten carbide coating for specialized needles and weaving tools. So, next time you see tungsten carbide coated tools, remember they have a wide range of industrial applications!

How to find a reliable supplier of tungsten carbide coatings?

Tungsten Carbide Coatings are a popular choice for industrial companies looking to improve the performance of their products. The benefits of tungsten carbide coating are many, and industries that commonly use this service include automotive, aerospace, and medical device manufacturing.

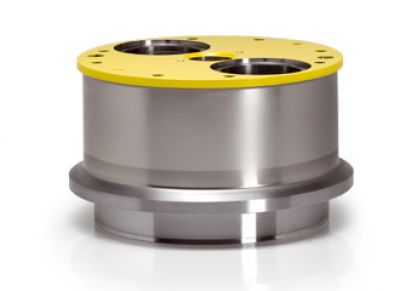

If you are looking for a reliable supplier of tungsten carbide coating services, Paganoni offers the best tungsten carbide coatings on the market: Coldside® coatings and Woldside® coatings. Contact us today to find out more about our products and how we can help you improve the performance of your business!

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy