Dynamic balancing on mechanical parts: test certificate

Blog and news on the world of wear-resistant coatings

Dynamic balancing on mechanical parts: test certificate

Are you in the drawing industry and looking for a reliable process that will ensure that your production line moves quickly and efficiently, without causing stress on machinery or risk of damage to mechanical parts? If so, dynamic balancing may be the solution you’ve been looking for. Dynamic balancing of mechanical parts is a precise technique used to reduce machine vibration and wear and to improve machining quality.

In this post we will explore how dynamic balancing works and discuss its many benefits for our customers in the drawing industry. Read on to find out why it should be an integral part of your production process!

What is dynamic balancing and why it is important

Today we talk to you about dynamic balancing and why it is so important. Simply put, dynamic balancing is the process by which you balance a rotating object, such as a wheel or crankshaft, reducing vibration and extending its life. This process is essential to ensure production safety, avoid damage to machine components, and improve the manufacturing experience.

Read also Polishing mechanical parts: how to recover them

Dynamic balancing is something that every industry should be familiar with and, if necessary, perform regularly. Mechanical parts wear out over time, so it is necessary to perform periodic checks and invest in their recovery and optimization.

Benefits of dynamic balancing on mechanical parts

Have you ever heard of dynamic balancing on mechanical parts? If you’re looking to achieve smoother and longer-lasting operation of your machines, then it’s time to learn about all the benefits this process has to offer. Dynamic balancing involves balancing the weight of all the individual parts of a machine to ensure even weight distribution on the rotating parts.

Read also Coatings for precision mechanical components: which ones are best

The end result? An industrial machine that operates without unwanted vibration, reduces wear and tear, and increases the service life of mechanical elements. Addressing the maintenance of your machine with dynamic balancing, but also dimensional checks and roughness checks, will surely make a big difference on your productivity, and this will save you money on repair and replacement costs of machine parts.

The dynamic balancing process in industrial production machines

This process is essential to ensure that machines operate properly, avoiding excessive vibrations that can cause damage to components and reduce their service life. In essence, dynamic balancing involves identifying any weight imbalances present within the rotating parts of machines and compensating for them to achieve perfect balance.

Through this process, maintenance costs are reduced and productivity is increased. That said, I would recommend that you always make sure your machines are dynamically balanced to ensure maximum performance and increased safety in the workplace.

Get a test certificate on the mechanical parts of your production

In summary, dynamic balancing is an important process that ensures that parts are kept in balance and maximized for performance. Industrial production machines require this process to be reliable, accurate and durable.

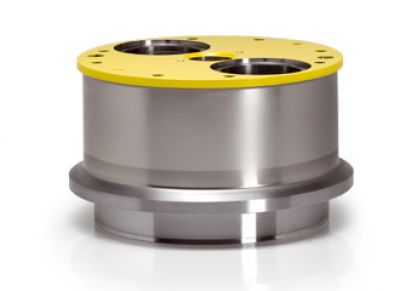

Paganoni specializes in coating mechanical parts and offers a service of test certificates to make sure they are properly balanced. This is essential to keep machine parts safe and efficient. If you are looking for a way to get a reliable test certificate for your mechanical parts, look no further than Paganoni-it has the expertise and years of experience to back it up.

Wait no longer: get your test certificate today!

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy