Sintered ceramic material: useful for mechanical parts

Blog and news on the world of wear-resistant coatings

Sintered ceramic material: useful for mechanical parts

If you work in the drawing industry, you know that sintered ceramic material is a useful tool for creating mechanical parts.

But what exactly is sintered ceramic material? And how can it be used to create high-quality mechanical parts?

Read on to find out!

What is sintered ceramic material and what are its benefits for mechanical parts?

Sintered ceramic material has become increasingly popular for wire drawing industries because of its many advantages. The strength and hardness of ceramics make it an excellent choice for creating mechanical parts that need to be strong and durable. The porosity of sintered ceramic also makes it very resistant to thermal shock, which is great news for mechanics who want their parts to withstand extreme temperature variations.

Learn more Wear-resistant ceramic coatings: why are they useful?

In addition, sintered ceramic parts are lightweight, so they do not add much weight to machinery. The low cost and availability make this type of material an attractive option for all mechanics looking for a reliable solution.

How does this type of material compare to other options on the market?

If you are looking for materials for mechanical parts, you will be happy to know that there are many options on the market. Among these materials, this type stands out for its durability and strength. Compared to other materials available on the market, this product has proven to be a better option for manufacturers looking for quality materials for their projects.

Read also Pulley and sheave: the importance of a quality coating

Its properties ensure reliable performance of any mechanical component in which it is used and make it a highly sought-after material.

Why are sintered ceramic materials a good choice for some kinds of applications?

Sintered ceramic materials are an attractive choice for many applications because of its advantages over other materials. It is incredibly durable, wear-resistant, and can withstand extreme temperatures without changing shape or size. For these reasons, it is an ideal choice for many roles such as filters, spark plugs, bearings and more that require materials that will not corrode or erode over time.

In addition to its beneficial qualities in terms of durability, sintered ceramic material also offers great electrical insulation properties compared to other materials and provides excellent electrical performance. Its unique properties make it a valuable option for those looking for the right material for their application.

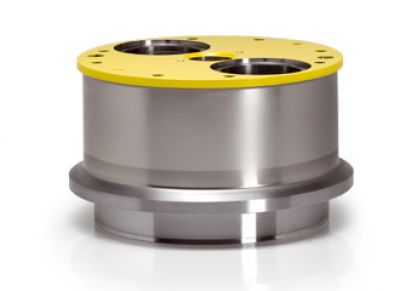

Are you familiar with Kersint® super-sintered ceramic material?

To recap, sintered ceramic materials have incredible advantages over other options on the market when it comes to mechanical parts. Not only are they strong and durable, but they also offer excellent corrosion resistance due to their oxide-based material. In addition, they are incredibly lightweight.

Because of all these advantages, sintered ceramics are an excellent choice for certain types of applications. Of course, no discussion of sintered ceramics would be complete without mentioning the super-sintered ceramic material Kersint®, which is much more resistant to corrosion and wear than traditional sintered ceramics due to its unique formulation of rare oxides and minerals. It is definitely worth exploring if you are looking for a reliable option that will not let you down in the most challenging scenarios. If you would like to learn more about this incredible material, feel free to contact us and find out now!

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy