Optimizing Production and Reducing Waste with Technical Coatings

Blog and news on the world of wear-resistant coatings

Optimizing Production and Reducing Waste with Technical Coatings

In the industrial wire drawing sector, every technological improvement implemented in the production process can become a tangible competitive advantage. In a context where operational efficiency, production continuity, and finished product quality are key performance indicators, technical coatings have established themselves as strategic tools for optimizing the entire production cycle. These are not merely protective materials — coatings act directly on the critical contact points of the process, where the wire meets mechanical components, helping to prevent wear, friction, and recurring failures.

In this scenario, reducing waste is not only an environmental or sustainability concern — it is a fundamental lever for improving business margins. Every off-tolerance part, every unplanned machine stop, and every extraordinary maintenance intervention represents a hidden cost that directly affects overall profitability. Technical coatings, such as those developed by Paganoni, are specifically engineered to target these friction points: they enhance component performance, extend service life, and ensure more stable and consistent operations over time.

This article offers a detailed analysis of how the strategic use of technical coatings can optimize production and minimize waste in wire drawing facilities. It presents practical case studies, measurable benefits, and operational guidelines to help you select the most suitable materials based on your production processes and plant objectives.

Interested in integrating Paganoni coatings into your production cycle?

Contact us for a free personalized consultation. Our technical team will guide you in selecting the coating best suited to your needs.

YOU MIGHT ALSO BE INTERESTED IN: The Compatibility of Coatings with Different Metal Alloys: Solutions for Wire Drawing

Technical Coatings: What They Are and Why They Make a Difference

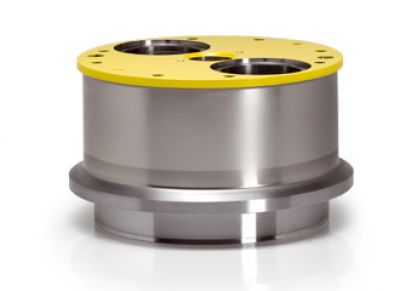

Technical coatings are a high-tech solution designed to protect and enhance the performance of mechanical components subjected to the most stress in industrial processes. In wire drawing, the main elements exposed to constant mechanical and thermal loads—such as capstans, drawing cones, return pulleys, wire guide rollers, and dancers—are in continuous contact with the wire, which generates friction, heat, and localized wear. Over time, these factors compromise both the quality of the process and the lifespan of the components involved.

By applying coatings based on tungsten carbides, chromium oxides, nickel, or sintered ceramic materials, Paganoni has developed solutions capable of transforming the functional behavior of surfaces—making them more wear-resistant, significantly reducing the coefficient of friction, and enhancing dimensional stability during operation. These improvements not only boost the machine’s overall performance but also significantly reduce the frequency of maintenance interventions and the need for component replacement over time.

For instance, WOLSIDE®, a coating applied through hot fusion, ensures superior durability thanks to its compact structure made of tungsten carbides and rare minerals. KERBLACK®, on the other hand, is ideal for dry applications due to its excellent corrosion resistance and its ability to eliminate issues related to galvanic currents. Both solutions offer concrete and measurable benefits in terms of increased productivity and reduced material waste.

The added value of technical coatings lies not only in their protective function, but also in their ability to improve the performance of the entire production line, delivering tangible results even in the short term.

Want to know which coating is best suited for your components? Speak with one of our specialized technicians. We’ll help you identify the most effective solution for your plant. Contact us for a technical consultation

How Coatings Influence Productivity

One of the most significant impacts of technical coatings is their ability to increase production efficiency by acting on multiple fronts simultaneously: speed, continuity, quality, and reliability. In wire drawing, each coated component becomes a performance enhancer, enabling ideal operating conditions to be maintained longer, even under heavy workloads or with challenging metals.

Take, for example, a WOLSIDE®-coated capstan. Its compact structure and ultra-low surface roughness allow the wire to pass smoothly, without micro-tears or slippage. This leads to faster wire drawing speeds, while also reducing vibrations and the risk of wire breakage. The result is a more stable production cycle, with fewer interruptions and a continuous flow of processed material.

Moreover, a coated surface that maintains its dimensional integrity longer allows for postponed maintenance schedules and extended intervals between unplanned downtime. This means fewer hours of machine stoppage and more hours of effective production, enabling better activity planning and a significant reduction in indirect costs.

The quality level of the finished product also improves. A smooth, consistent, and stable wire drawing process yields wires with tighter dimensional tolerances and more uniform surfaces. These advantages extend downstream, improving final product quality and boosting customer satisfaction.

Lastly, it’s worth noting that a more productive plant is also more competitive in the market, as it can respond more quickly to orders, ensuring shorter delivery times and greater overall reliability.

Looking to increase productivity without investing in new equipment? Consider incorporating Paganoni’s technical coatings into your operations. Request a tailored technical consultation.

Reducing Waste: Fewer Rejects, Greater Efficiency

In manufacturing, every meter of rejected wire represents a cost—wasted material, energy, and machine labor hours. Often, non-conformities are not the result of major errors, but rather of minor imperfections in the wire drawing components: an overly worn pulley, a cone with excessive roughness, or a capstan that has lost traction on the wire.

In such cases, technical coatings serve as the first line of defense against waste generation.

When using high-performance coatings like KERBLACK® or KERSINT®, the contact between the wire and the component becomes more uniform, stable, and controlled. This results in:

- Lower risk of wire ovalization

- Cleaner wire surfaces, free from scratches or abrasions

- Fewer breaks caused by friction or overheating

In particular, KERSINT®, a sintered ceramic coating with exceptional chemical and mechanical resistance, is ideal for production lines that handle wire in acidic environments or high temperatures, where traditional components degrade quickly, leading to continuous rejects and quality issues.

Another key benefit is the dimensional stability of coated components over time. A cone or pulley that retains its original profile after hundreds of production cycles helps prevent misalignment, slippage, and deviation—factors that often cause rejects and disrupt the entire production flow.

The result is fewer reworks, less remanufacturing, and smoother quality control procedures.

Beyond reducing direct waste, technical coatings also optimize production parameters to minimize indirect waste, such as energy consumed per good part produced or labor hours per compliant batch.

Dealing with excessive scrap rates in your wire drawing line? Paganoni can help identify mechanical causes and recommend the most effective coating to prevent them.

Contact our technical team.

YOU MIGHT ALSO READ: Wolside® vs Kerblack®: Which Coating Should You Choose for Your Wire Drawing Line

The Strategic Role of Component Recovery

In an industry where each component is a significant investment and every unplanned stoppage can have serious financial consequences, the recovery of worn components is gaining strategic importance. Paganoni has developed a specialized technical regeneration service that restores the original geometry of damaged capstans, cones, and pulleys through the application of its high-performance wear-resistant coatings.

This approach not only extends the lifecycle of expensive components, but also represents a sustainable solution, aligned with the principles of circular economy. Instead of replacing a worn part entirely, it can be regenerated with coatings such as WOLSIDE®, KERBLACK®, or COLDSIDE®, achieving a result that is often equal to—or even better than—a new component.

A practical example: restoring a worn capstan with a KERBLACK® coating on the pulling surface enables the part to withstand another full production cycle, with high resistance to abrasion and galvanic corrosion, especially in dry processes. Furthermore, the controlled roughness of the coated surface ensures optimal interaction with the wire, minimizing friction and overheating.

Another major benefit is the speed of the intervention. Paganoni’s recovery service also includes internal cleaning of the capstans to remove scale deposits that interfere with cooling. This preventive maintenance helps avoid future failures and enhances system performance.

Component recovery is therefore a dual lever:

- Economically, it reduces purchase costs

- Functionally, it improves system reliability

Do you have worn or damaged components in your production line? Let’s evaluate a regeneration plan together. Our team is ready to support you with fast, effective, and certified solutions.

Case Study: Improved Production Performance with WOLSIDE® and KERBLACK®

To truly understand the impact of technical coatings in a production environment, it is helpful to examine a real-world case. A European company, one of the leading manufacturers of wire for the automotive industry, approached Paganoni with a clear goal: increase the production speed of its dry wire drawing line, while also reducing maintenance costs and scrap rates.

Following a thorough assessment of the operating conditions, Paganoni proposed the combined use of two technical solutions:

This recommendation was based on the superior wear and impact resistance of WOLSIDE®, combined with the exceptionally low surface roughness and anti-seizing properties of KERBLACK®.

After six months of operation, the results were both measurable and significant:

- +35% increase in production speed without compromising quality

- -50% reduction in scheduled maintenance interventions

- +20% increase in the average service life of components compared to non-coated versions

- -15% decrease in scrap due to wire breakage or dimensional defects

These results led to a positive ROI within the first quarter, thanks to a reduction in non-productive machine hours, greater cycle stability, and improved overall line reliability.

An additional benefit was observed at the organizational level: with more durable and efficient components, maintenance activities could be rescheduled with greater flexibility, freeing up technical resources for higher-value tasks.

This case study clearly demonstrates how the strategic integration of Paganoni’s technical coatings is not just a technical fix, but a true industrial lever for enhancing competitiveness and profitability.

Want to learn how these results can be replicated in your plant? Our team can support you with a customized preliminary analysis and tailored recommendations. Request a consultation.

Conclusion

Optimizing production and reducing waste is not a theoretical goal — it is a concrete necessity for any company that aims to maintain competitiveness, efficiency, and economic sustainability over the medium to long term. As we’ve seen, technical coatings provide tangible, measurable solutions to the critical challenges of wire drawing: from accelerated component wear and machine downtime to processing waste and extraordinary maintenance costs.

Success stories, such as the one outlined above, prove that selecting the right materials and adopting advanced technologies like WOLSIDE®, KERBLACK®, KERSINT®, COLDSIDE®, or NIKSINT® can have a profound impact on the entire production cycle.

It’s not just about protecting a capstan or a pulley — it’s about optimizing a system, making production smoother, more predictable, and easier to manage.

In today’s industrial landscape, where the demand for performance continues to rise along with pressure on margins, investing in high-quality technical coatings means maximizing every resource: materials, machines, labor, and time. It’s a deep, structural strategy that improves key productivity parameters and sets the foundation for leaner, more economical, and more advanced industrial management.

Paganoni offers not only best-in-class coatings but also specialized technical consultancy, component recovery services, and ongoing support to tailor every solution to the customer’s specific production needs.

Looking to turn your production process into a strategic growth lever? Rely on Paganoni’s proven expertise.

Do you want more information or request a free and no obligation quotation?

The our products Paganoni

Fiscal code 00231210139

VAT number IT 00758810147

R.E.A. Lecco n. 128509

Fully paid-up capital €1.138.882,50

Address

Registered office:

Via dei Livelli, 6

IT 23842 - Bosisio Parini (LC)

Operational headquarters:

Via XXV Aprile, 44

IT 23841 - Annone di Brianza (LC)

Contacts

-

PEC: marionava@legalmail.it

-

+39 031 87.62.10

© Paganoni. Mario Nava S.p.A. Tutti i diritti riservati. | Privacy Policy | Termini d'uso | Cookie Policy