Industrial Resilience: Anti-Wear Coatings that Prolong Component and Machine Life

In the competitive world of metal drawing, the longevity and efficiency of mechanical components are crucial to success.

A key element that contributes to this durability is the use of advanced anti-wear coatings. These play a crucial role in ensuring that machinery operates at optimum levels, reducing maintenance costs and improving productivity.

In this context, Paganoni stands out with its many years of expertise and cutting-edge product range.

Durability Issues of Mechanical Components

The endurance and long life of mechanical components can make the difference between the performance of a machine and its decay. The wire drawing industry, more than many others, is characterised by extreme environmental conditions, high levels of friction and mechanical stress, which constantly put machines to the test.

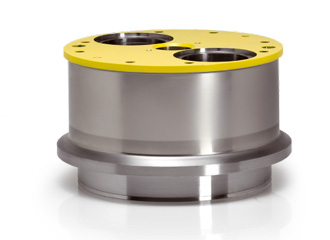

Cables, rings, cones and other parts are subjected to considerable pressure during the drawing process, making it essential to find solutions that prolong their life. The lifetime of these components directly affects production, finished product quality and maintenance costs.

Wear Coatings in the Wire Drawing Industry

Wear coatings provide an essential barrier between components and the forces acting on them.

The use of state-of-the-art technologies such as those offered by Paganoni – Wolside®, Kerblack®, Kersint® and Coldside® – has proven to be crucial in maintaining components in optimum operating condition.

By reducing wear and seizure, thanks to materials such as ceramic and zinc, these coatings not only prolong the life of components but also help to improve the overall efficiency of machinery.

READ ALSO: Ceramic coating for mechanical parts

Innovation for Industrial Sustainability: Longevity and Superior Performance

Meeting the challenges of the wire-drawing industry is a cornerstone of Paganoni, which has created a versatile range through research and development of high-impact materials.

Products such as Wolside®, with its super-compact tungsten carbide coating, and Kerblack®, with its resistance to seizing and corrosion, are tangible examples of how technology can be applied to ensure maximum component durability and performance.

The Kersint® coating, based on zirconium oxide, and Coldside®, for the reinforced concrete industry, show Paganoni’s commitment to providing solutions for a wide variety of applications. These coatings not only improve wear resistance but also help to reduce maintenance costs and balance production processes, with a view to sustainability right from the outset.

Paganoni’s anti-wear solutions therefore go far beyond simple component protection. They play a key role in promoting more efficient, sustainable and competitive machinery.

Investing in advanced coatings is not only a prudent choice for component longevity, but a key strategy for thriving in the dynamic environment of the wire drawing industry.