Wolside® vs Kerblack®: Which Coating Should You Choose for Your Wire Drawing Line?

The Importance of Wear-Resistant Coatings in Wire Drawing

In the wire drawing industry, the choice of materials and surface coating technologies applied to mechanical components has a direct and significant impact on the entire production process. Components such as drawing cones, capstans, rings, pulleys, and wire guides are constantly exposed to high mechanical and thermal stress, as well as friction, wear, and corrosion. In this context, the use of high-performance wear-resistant coatings is not merely a technical choice—it is a strategic lever for improving reliability, productivity, and profitability across the plant.

The primary function of these coatings is to extend the operational life of key components, while ensuring long-term dimensional stability, high-quality contact surfaces, and a significant reduction in friction. These benefits result in less frequent maintenance interventions, lower overall operating costs, and more consistent, uninterrupted production. Moreover, the quality of the drawn wire—be it copper, carbon steel, stainless steel, or specialty alloys—depends heavily on the surface precision and condition of the components involved in the drawing process.

Specifically, Paganoni’s Wolside® and Kerblack® coatings are the result of decades of research, testing, and partnerships with leading manufacturers and users of wire drawing equipment. The company’s deep specialization in anti-wear coating technology has led to the development of solutions that address key industry challenges such as mechanical wear, galling, and chemical corrosion, especially in dry and wet drawing environments.

In an industrial landscape where every unscheduled machine stop can generate substantial financial losses, selecting the appropriate coating for each critical component becomes a measurable competitive advantage.

Looking to reduce machine downtime and maximize the efficiency of your wire drawing line? Contact us for a personalized technical consultation on the most suitable coatings for your system.

What Is Wolside®: Composition, Benefits, and Applications

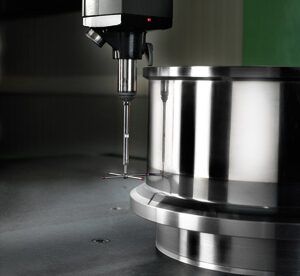

Wolside® is one of the most advanced technical coatings developed by Paganoni for the wire drawing industry. It is a hot-fused coating—applied through Hot Isostatic Pressing (HIP)—based on tungsten carbides and rare minerals. This composition ensures exceptional density, compact structure, and outstanding wear resistance. Its physical and chemical properties make Wolside® particularly well-suited for components subject to intense mechanical stress, as typically found in both dry and wet wire drawing operations.

One of Wolside®’s key strengths is its superior resistance to abrasive and impact wear. This directly translates into a longer operational life of coated components, even under extreme conditions. In addition, the coating significantly reduces the coefficient of friction between the wire and the component, thereby improving the efficiency of the drawing process and enhancing the quality of the final product.

Among its measurable benefits, Wolside® enables higher production speeds without compromising quality, while also lowering costs related to frequent part replacement and machine downtime. Its very low surface roughness (Ra) ensures smooth and controlled contact with the wire, minimizing micro-damage and increasing overall plant efficiency.

Main Applications of Wolside®:

- Drawing capstans (entry and exit)

- Drawing cones and rings

- Wire guide rollers

- Return pulleys and dancer pulleys

- Counters and special mechanical parts

Thanks to its versatility, Wolside® can be applied to a wide range of metallic materials, including carbon steel, stainless steel, copper, and specialty alloys. It is also suitable for geometrically complex components or those requiring high surface finish precision.

The efficiency and reliability achieved with Wolside® have been validated by numerous international companies, which rely on it daily to enhance line performance and extend component life cycles.

Want to find out if Wolside® is the right solution for your components?

Request a free technical assessment tailored to your wire drawing line.

What Is Kerblack®: Technical Features and Use Cases

Kerblack® is a high-performance ceramic coating developed by Paganoni, specifically engineered to meet the demands of dry wire drawing applications for both ferrous and non-ferrous metals. Its formulation is based on chromium oxides, a material renowned for its exceptional hardness, chemical inertness, and resistance to galling, even under aggressive operating conditions. This coating stands out for its ability to dramatically reduce the friction coefficient and eliminate phenomena such as galvanic corrosion and passive currents.

One of Kerblack®’s most critical strengths is its ability to shield mechanical components from corrosion, even when used in dry environments rich in metallic dust or subject to elevated contact friction. The coating forms a uniform, compact ceramic barrier that preserves contact surfaces and ensures the dimensional and geometric stability of components over time.

From a performance standpoint, Kerblack® offers:

- An extremely smooth surface finish that improves wire quality

- Fewer production defects and reduced rework

- Higher drawing speeds, without compromising surface quality

- Extended component lifespan, thanks to enhanced abrasion resistance

Another key advantage of Kerblack® is its suitability for refurbishing worn components such as capstans and pulleys. Using an advanced deposition process, it is possible to rebuild and restore parts to full working condition, cutting costs and lead times compared to full replacement. This makes Kerblack® ideal for sustainable maintenance strategies focused on lifecycle optimization.

Main Applications of Kerblack®:

- Drawing cones for dry wire drawing

- Drums and rings for enameling lines

- Return pulleys made of aluminum

- Wire guide rollers and lightweight capstans

- Parts for PCB printing systems and precision spacers

Kerblack® is the preferred solution for industrial applications that require surface precision, chemical resistance, and anti-galling performance under demanding dry drawing conditions.

Do you use aluminum components or operate with dry drawing processes?

Contact us to receive technical guidance on applying Kerblack® to your systems.

Direct Comparison: Wolside® vs Kerblack®

While Wolside® and Kerblack® share the common goal of extending the service life of wire drawing components and improving overall plant performance, each coating is designed to address specific operational requirements. Therefore, a detailed comparison of their technical and functional differences is essential to support an informed decision based on your production environment and the type of material being processed.

Composition and Application Technology

Wolside® is a metallic coating created through hot isostatic pressing (HIP) and composed primarily of tungsten carbides, a material known for its exceptional hardness and mechanical strength. This treatment ensures a compact, robust structure and excellent impact and abrasion resistance, making it ideal for components exposed to high dynamic stress and direct metal-to-metal contact.

Kerblack®, by contrast, is a ceramic coating based on chromium oxides. The deposition process produces an extremely smooth and chemically stable surface, offering superior protection against corrosion and galling. It is particularly effective in dry drawing applications, where the absence of lubrication increases the risk of friction-induced wear and surface degradation.

Wear Resistance and Operating Conditions

- Wolside® performs exceptionally well in applications involving high mechanical loads, such as the drawing of ferrous wires, ribbed wires, or wires processed in wet conditions, where components are subject to repeated impact, vibration, and intense friction.

- Kerblack® is the ideal solution for operations without lubrication, especially in the drawing of light metals such as aluminum and copper, where achieving an excellent surface finish and chemical protection is critical.

Maintainability and Recoverability

Another key difference is the recoverability of components. Thanks to its ceramic nature, Kerblack® can be applied as a rebuild coating on worn parts, restoring full functionality with performance comparable to new components. While Wolside® offers superior mechanical durability, it is less flexible for reconditioning.

Summary of the Comparison

In short:

- Choose Wolside® when operating in dynamic environments that demand high-speed production and mechanical robustness.

- Choose Kerblack® when chemical stability, anti-galling properties, and surface quality are your priorities.

Need to evaluate the performance of your current coatings against Paganoni’s solutions? Request a free comparative analysis based on real-world applications.

Selection Criteria: Which Coating Is Right for You?

Choosing the most suitable wear-resistant coating is not a one-size-fits-all decision. It requires a detailed assessment of your production environment, the types of metals being drawn, the characteristics of your wire drawing line, and the technical challenges encountered during operation. While both Wolside® and Kerblack® deliver high-level performance, each is engineered for distinct scenarios and specific industrial needs.

1. Type of Metal Being Drawn

The first key consideration is the type of wire material used.

- If your equipment handles ferrous wires, carbon steels, stainless steels, or ribbed wire for reinforced concrete, Wolside® is the ideal choice. It is built for extreme mechanical demands and designed to withstand constant operational stress.

- On the other hand, if you’re drawing softer metals like copper or aluminum, or operating in conditions where surface finish is critical, Kerblack® offers the right level of smoothness, chemical resistance, and precision.

2. Drawing Method: Wet vs. Dry

The drawing process type is also a critical factor.

- In wet drawing operations, where lubricant is present and the equipment operates at high speed and stress levels, Wolside® delivers exceptional wear resistance and durability.

- In dry drawing, where direct friction and high surface temperatures are common, Kerblack® excels due to its low-friction, anti-galling surface and chemical inertness.

3. Lifespan and Maintenance Strategy

- If you aim to maximize mechanical strength and component life in high-output plants, Wolside® ensures long-lasting dimensional stability and reliability.

- If you’re looking to optimize maintenance and reduce replacement costs, Kerblack® stands out for its recoverability and suitability for re-coating worn parts with minimal downtime.

4. Strategic Investment Objectives

Finally, ask yourself: What is my operational priority?

- If you’re focused on maximizing mechanical performance and production speed, Wolside® is your go-to solution.

- If you’re aiming to minimize equipment stoppages, protect against chemical wear, and ensure surface integrity, then Kerblack® is the most strategic choice.

Do you need expert guidance to choose the optimal coating for your equipment?

Contact us for a tailored assessment based on your technical specifications and performance goals.

Conclusion

In the highly technical and competitive world of industrial wire drawing, every component, every engineering choice, and every process detail has a measurable impact on product quality, production continuity, and profitability. In this context, the coating of wear-prone components is not a secondary consideration—it is a strategic factor.

As we’ve outlined, Wolside® and Kerblack®, both developed by Paganoni, represent two technologically advanced solutions, each with a clearly defined focus:

- Wolside® is the premium choice for plants requiring maximum mechanical resistance, high performance, and extended durability in components operating under intense dynamic stress, such as capstans for ribbed wire or cones used in wet drawing lines.

- Kerblack®, in contrast, is the ideal response for dry wire drawing operations, especially with non-ferrous or aluminum components, where chemical protection, anti-galling properties, and surface finish quality are top priorities.

In an industrial setting where demands include fast lead times, minimal interventions, and consistent output quality, selecting the right coating can be the decisive factor between a standard operation and a system that performs at maximum efficiency for years. The good news is: you’re not alone in making this decision. Paganoni provides access to a team of specialized technical experts ready to analyze your production setup, identify pain points, and recommend the most effective, sustainable, and cost-efficient coating solution for your goals.

Thanks to the flexibility of Paganoni’s product line, it’s also possible to integrate coatings into preventive maintenance strategies, energy optimization plans, and continuous improvement programs, reducing waste and maximizing the long-term value of your equipment.

Your production line deserves to operate at its full potential. Get in touch today to schedule a technical inspection or request a tailored quotation